Production

AMS Reverse Engineering: Production and Spares Capabilities

Aerospace Maintenance Solutions, LLC (AMS) is now certified to AS9100D requirements. In addition to repairing and overhauling military aircraft components with its AS9110C certification, AMS can now produce new units for legacy aircraft, and thereby solve Diminishing Manufacturing Sources and Material Shortages (DMSMS) issues.

Sometimes we can take multiple non-functioning units, disassemble them, and piece together a complete functioning unit that can be purchased as an airworthy spare. But in other cases, the only choice is to reverse engineer components that are no longer available for sale on the open market. AMS specializes in supporting military aircraft components with DMSMS resulting from various reasons, including:

-OEM for critical parts go out of business.

-Small parts, consumables, or subassemblies that support legacy components cannot be procured.

-Large corporation sometimes acquire smaller companies and target specific product lines while lesser valued parts fall to the wayside and are not supported.

-There are no known competitors for the part number.

Reverse engineering is the process of duplicating an item that has been previously tested and proven flightworthy but is no longer available for sale. These items may not be available because the Original Equipment Manufacturer (OEM) has gone out of business, or maybe because there are internal components that can’t be purchased for new units and repairs, or for other reasons.

Reverse engineering an item means replicating it’s fit, for, function, function, and dimensions. It is often a preferred process of duplicating an item because has been previously tested and proven flightworthy. At Aerospace Maintenance Solutions, LLC (AMS), we accomplish this process for military aircraft components following AS Quality practices; by using a library of authenticated manuals, technical documents, and drawings; and by following US Department of Defense guidelines for reverse engineering.

Reverse engineering reduces procurement costs of spare and replacement parts for units that have only one or no current manufacturer. Spares and replacements units constitute a large share of the defense budget. Scrutiny of the cost for spare parts has necessitated the need for greater competition in these sections of defense budgets for the U.S. Air Force, Army, Marines, Navy, and Homeland Security. The U.S. Congress and the Department of Defense implemented the Defense Acquisition Regulation Supplement No. 6 (DAR-S6), titled: DOD Replenishment Parts Breakout Program, which was created to encourage competition and reduce restrictive features that limit competitive procurement.

Military aircraft end users need new sources for component repairs, overhauls, spares, and replacement components to support ongoing maintenance and enable the mission readiness of their aircraft. AMS solves these and other sustainment issues.

Sustaining Legacy Military Aircraft

Aerospace Maintenance Solutions, LLC (AMS) is dedicated to sustainment of legacy military aircraft. Sustainment is achieved through our AS Quality system processes.

Our official Scope of Registration is two-fold:

AS9110D: Design, development, and production of aircraft components.

AS9100C: Maintenance, repair, and overhaul activities.

As a Prime Contractor, we design, develop, and engineer aircraft components that meet fit, form, and function requirements of our customers.

Our vendors are “source-directed” by AMS. They operate under the direction and authority of AMS.

Using a collaborative approach to aircraft sustainability supports AMS engineering and production initiatives, which include the following:

Identifying Diminishing Material Source (DMS) Issues:

AMS has decades of experience in repair and overhaul, which enables DMS identification by AMS.

Merger and acquisition activities create many DMS issues, particularly the lack of OEM component support from OEM. Legacy aircraft are vulnerable to DMS due to decreasing volume and lack of sub-tier vendors.

Mitigating OEM Lack of Interest and Support:

AS9100C processes are used to develop replacement subassembly components.

AMS produces entire next higher assemblies and obtains approvals from end users or aircraft OEM.

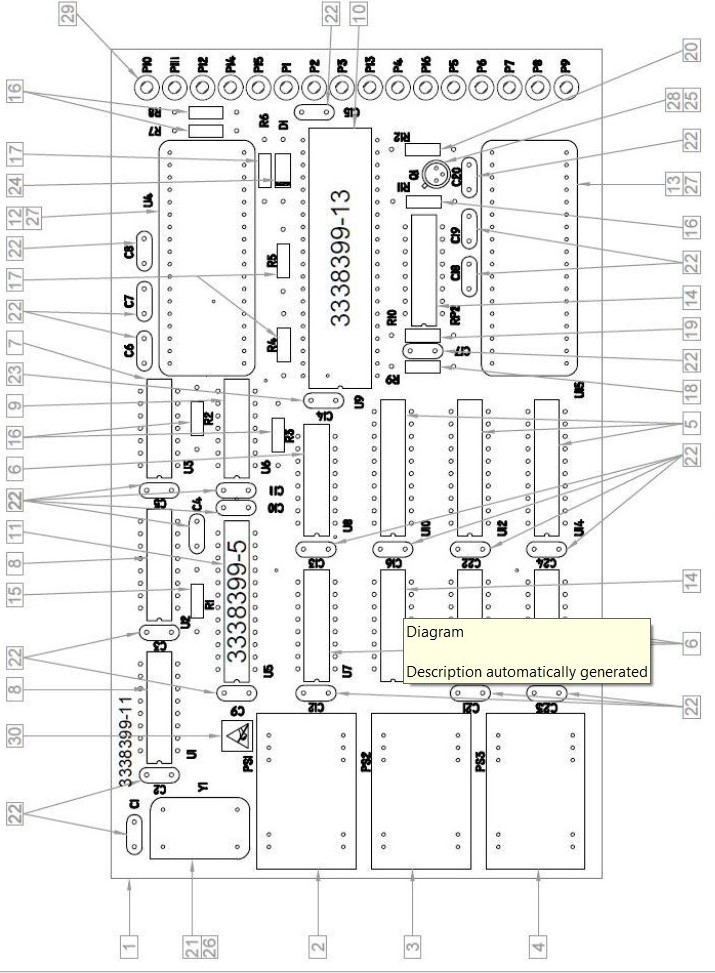

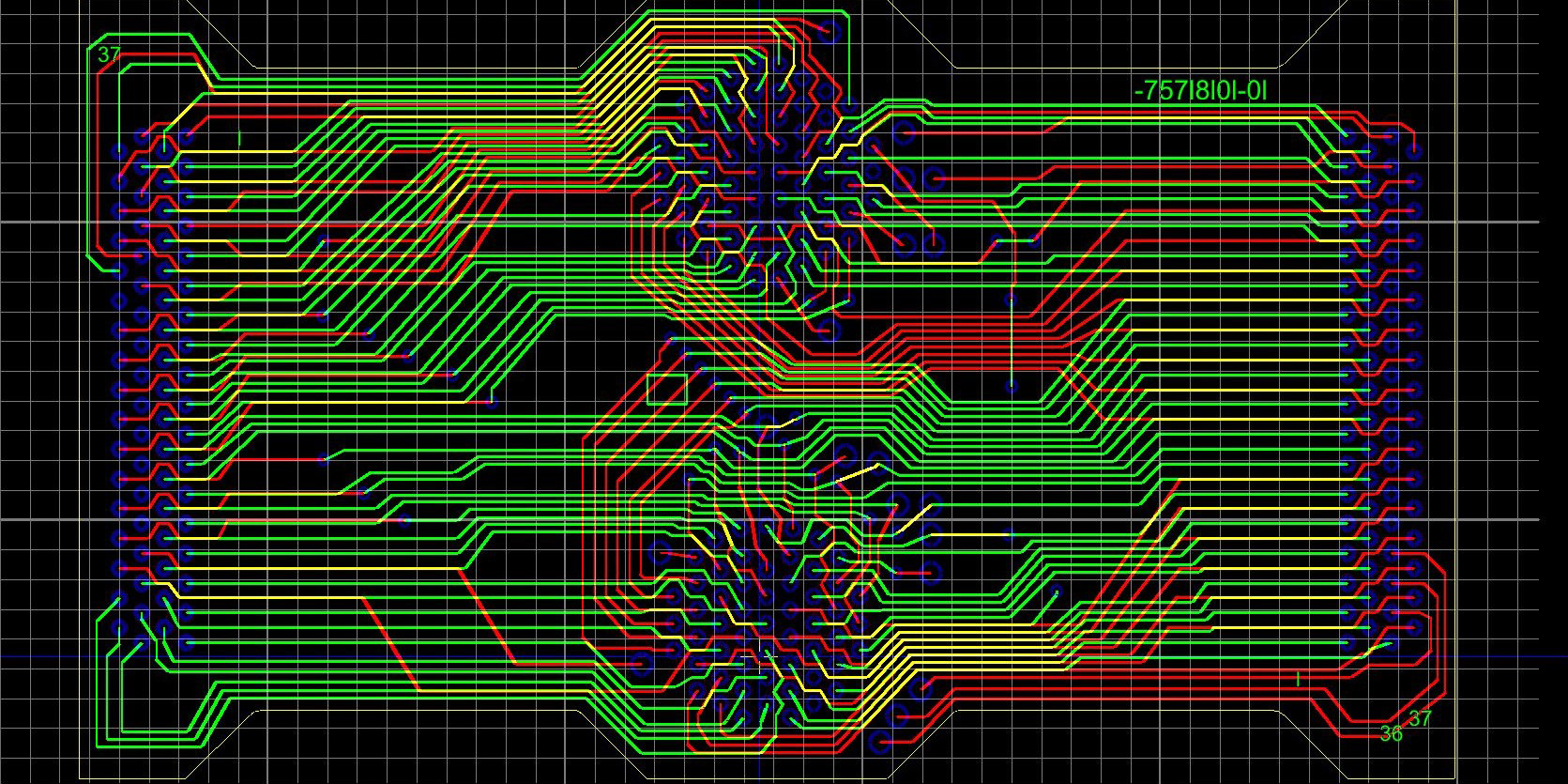

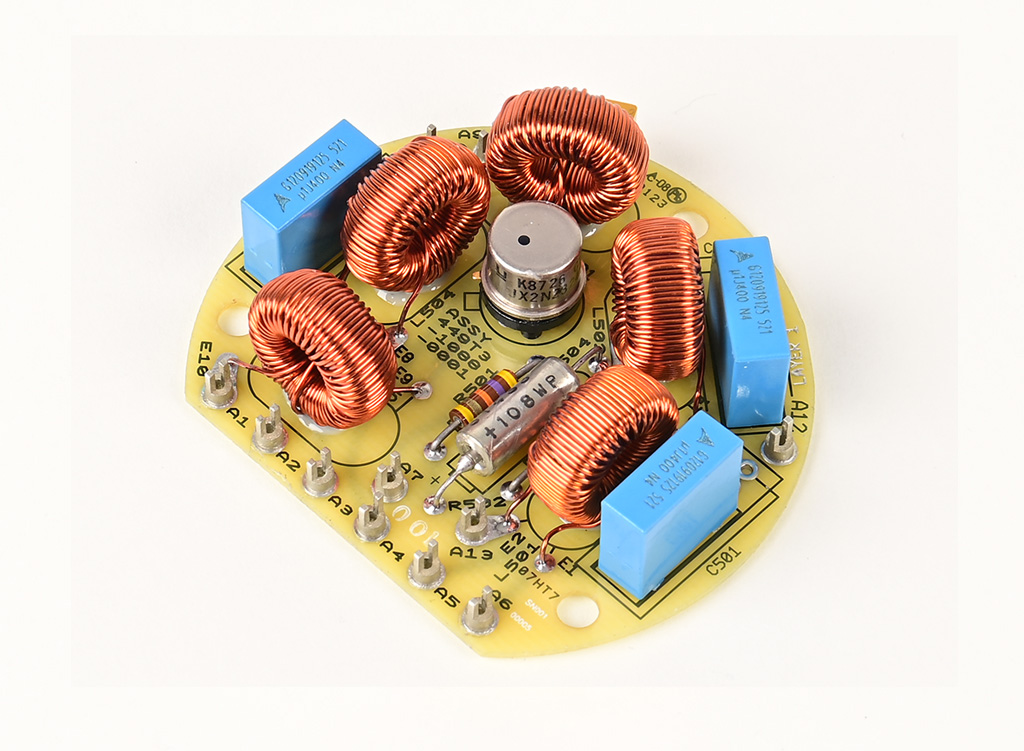

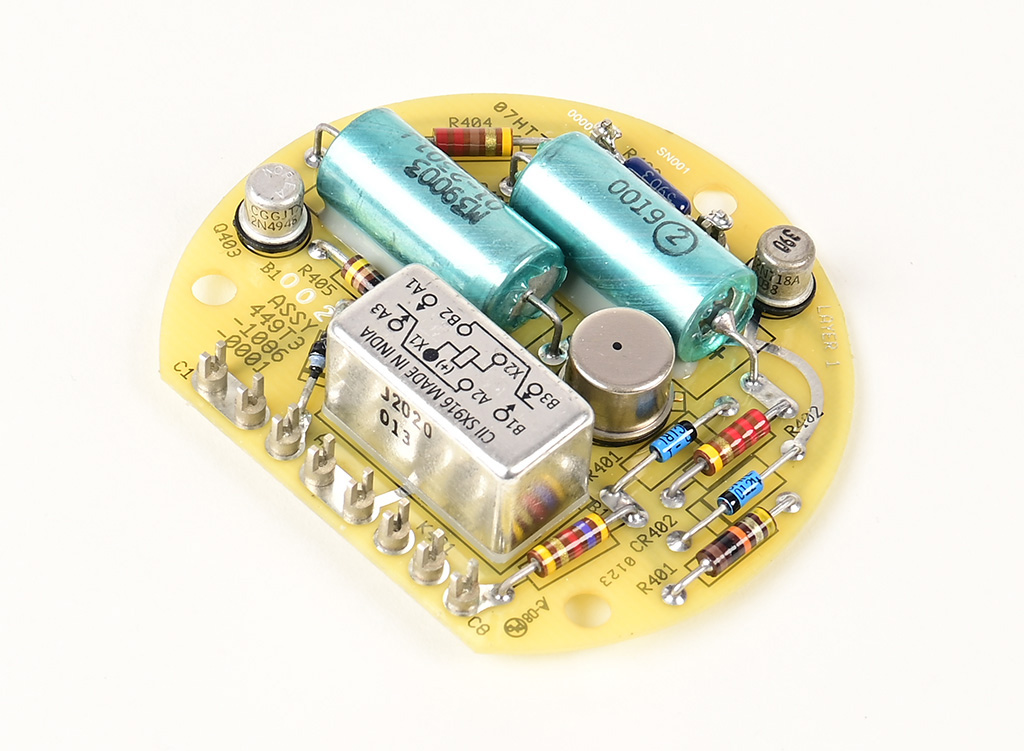

Supporting Electronics Items:

AMS has specialized vendors for Military Grade PCB phenolic production.

Our units meet IPC-600 IPC-610, and JSTD-001 standards.

Supporting Electro-Mechanical Assemblies:

AS9100C design and development activities are source directed for rotor and stator wire rewinding.

All source-directed activities comply with AMS specifications.

Supporting Mechanical Components:

A long history of contracts with proven AS9100C/ISO aerospace and defense OEM.

Services include machine shop CNC machining, metal and plastic mold casting, etc.

Processing of parts completed in accordance with AMS drawings and specifications.

For more information, contact bwiebusch@aerospacellc.com