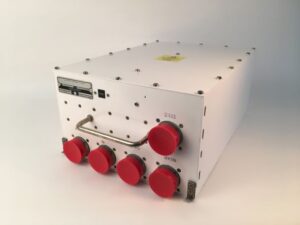

AMS Produces New Batteries for F-16’s Expanded Fire Control Computer

Solon, OH – Aerospace Maintenance Solutions, LLC (AMS) announces the company is the sole source of new Battery Modules for

AMS performs maintenance, repair, and overhaul services required to maintain aircraft instrumentation, radar, radio communication, electrical/electronics system components, and mechanical accessories (including hydraulic and pneumatic components) to support the military, police, and others in the aerospace industry.

We specialize in maintaining components that are no longer actively supported by their OEMs. AMS often provides shorter lead times and better pricing.

Proven solutions for the efficient repair and overhaul of military aircraft components

Solon, OH – Aerospace Maintenance Solutions, LLC (AMS) announces the company is the sole source of new Battery Modules for

Solon, OH — Samuel Kim, Issac Kim, and David Choi are members of the Robotics of the Future team from

Solon, Ohio — Engineers Rich Loy, John Nauman, and Rob Romano from the U.S. Navy recently monitored testing and performance

Solon, OH – The U.S. Department of Defense (DoD) announced in December of 2024 that it has awarded a contract

With AS9100D certification, AMS can offer a wider range of service options to military aircraft end users, particularly in the area of legacy aircraft components.

Solon, OH – For seventeen years Aerospace Maintenance Solutions (AMS) has been providing maintenance, repair, and overhaul services for military

Solon, OH – The Air Force Sustainment Center (AFSC) at Hill Air Force Base in Utah has approved Aerospace Maintenance

Solon, OH — Aerospace Maintenance Solutions, LLC (AMS) announces Northrop Grumman approval as a certified supplier to support a wide

Solon, OH – The U.S. Air Force Sustainment Center at Hill Air Force Base in Utah has approved Aerospace Maintenance

Brook Park, Ohio — Aerospace Maintenance Solutions (AMS) participated in a signing ceremony with Ohio Aerospace Institute’s President Dr. John